Introduction

In this reflection, I will describe our experience in assembling a Prusa Mini+ 3D printer, calibrating it to print a 3D Benchy, and exploring effective documentation and troubleshooting techniques. My collaborator, Isabel, and I approached this project with determination, navigating the challenges and successes that came our way.

Documentation

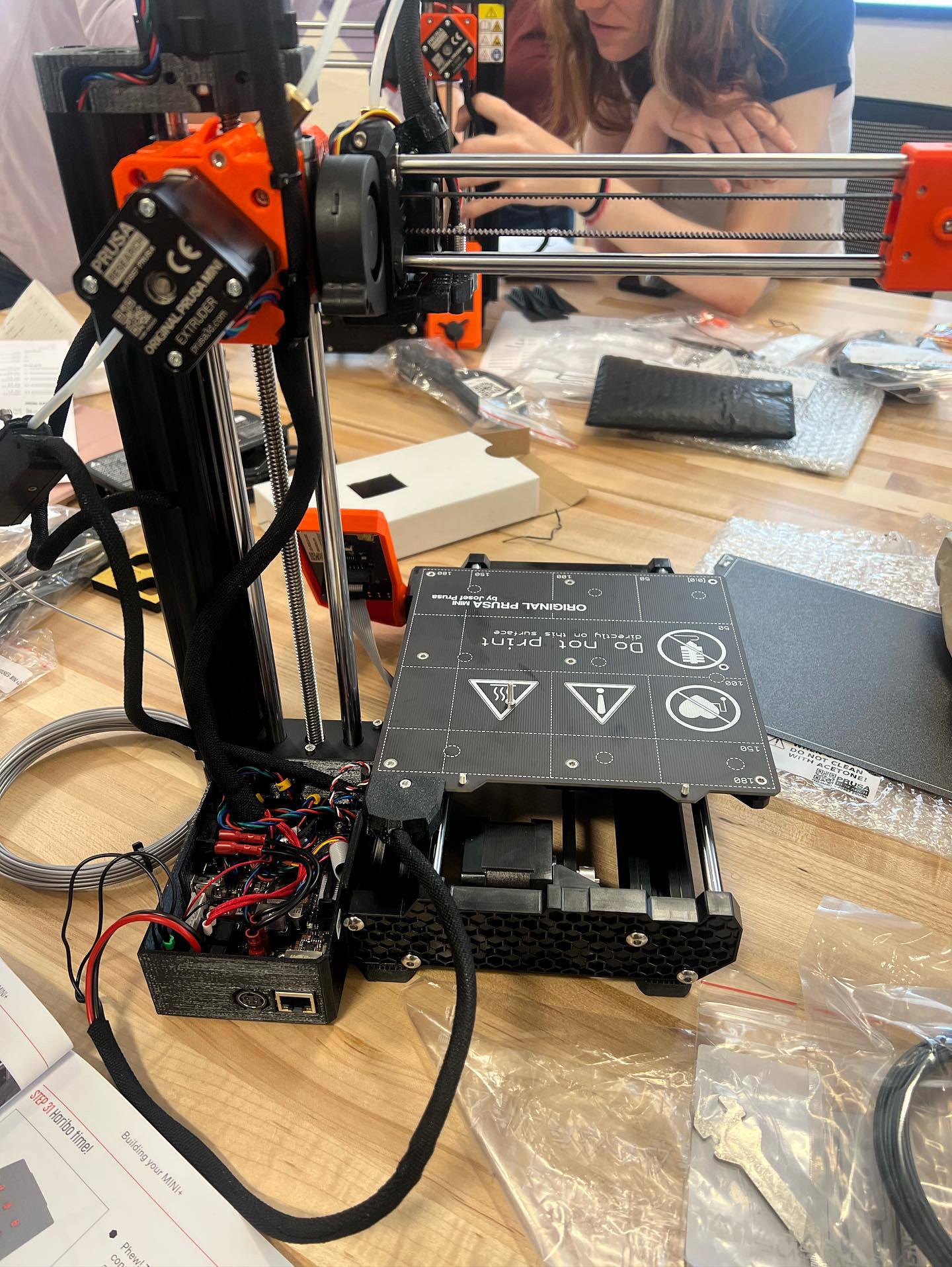

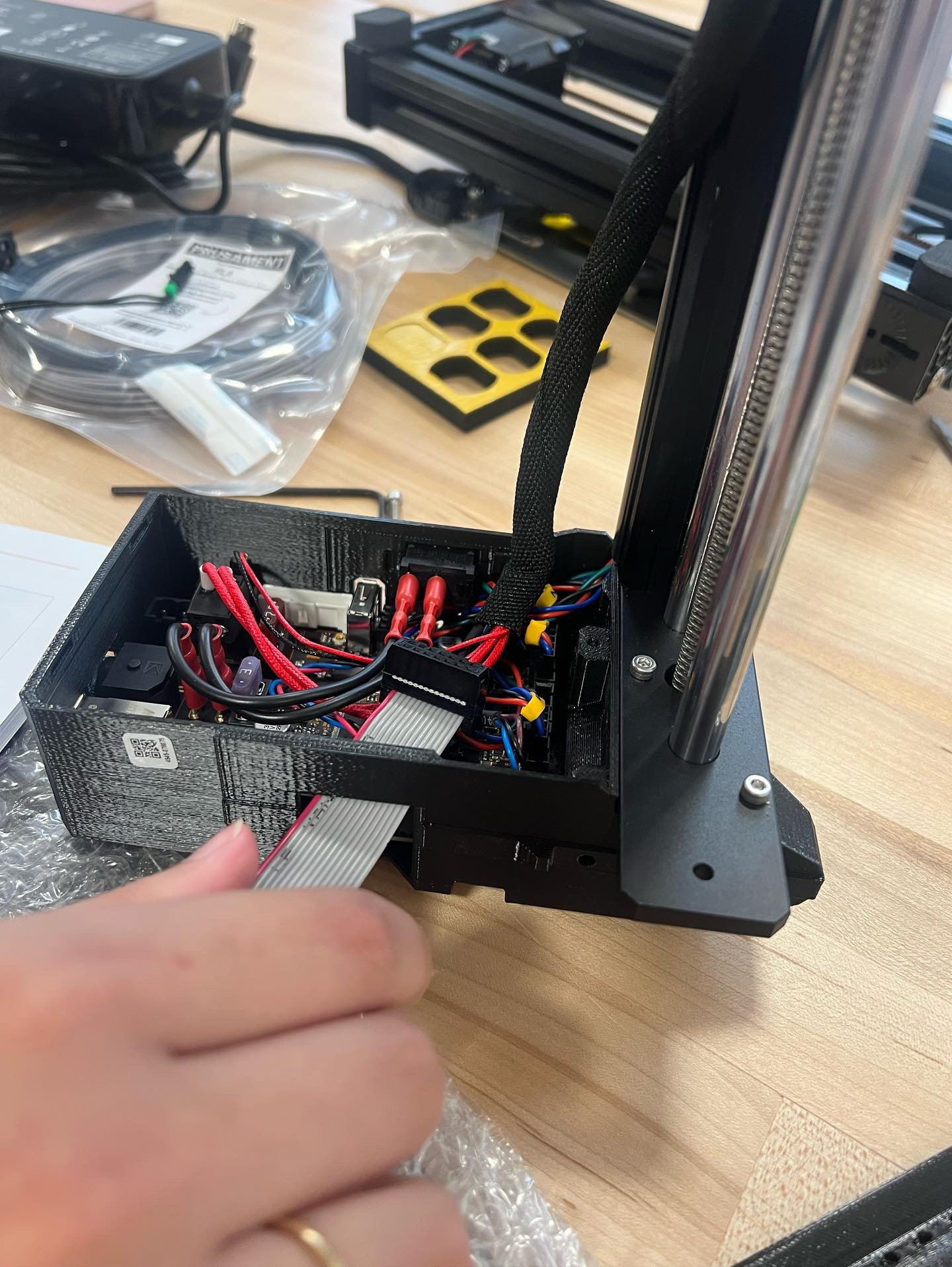

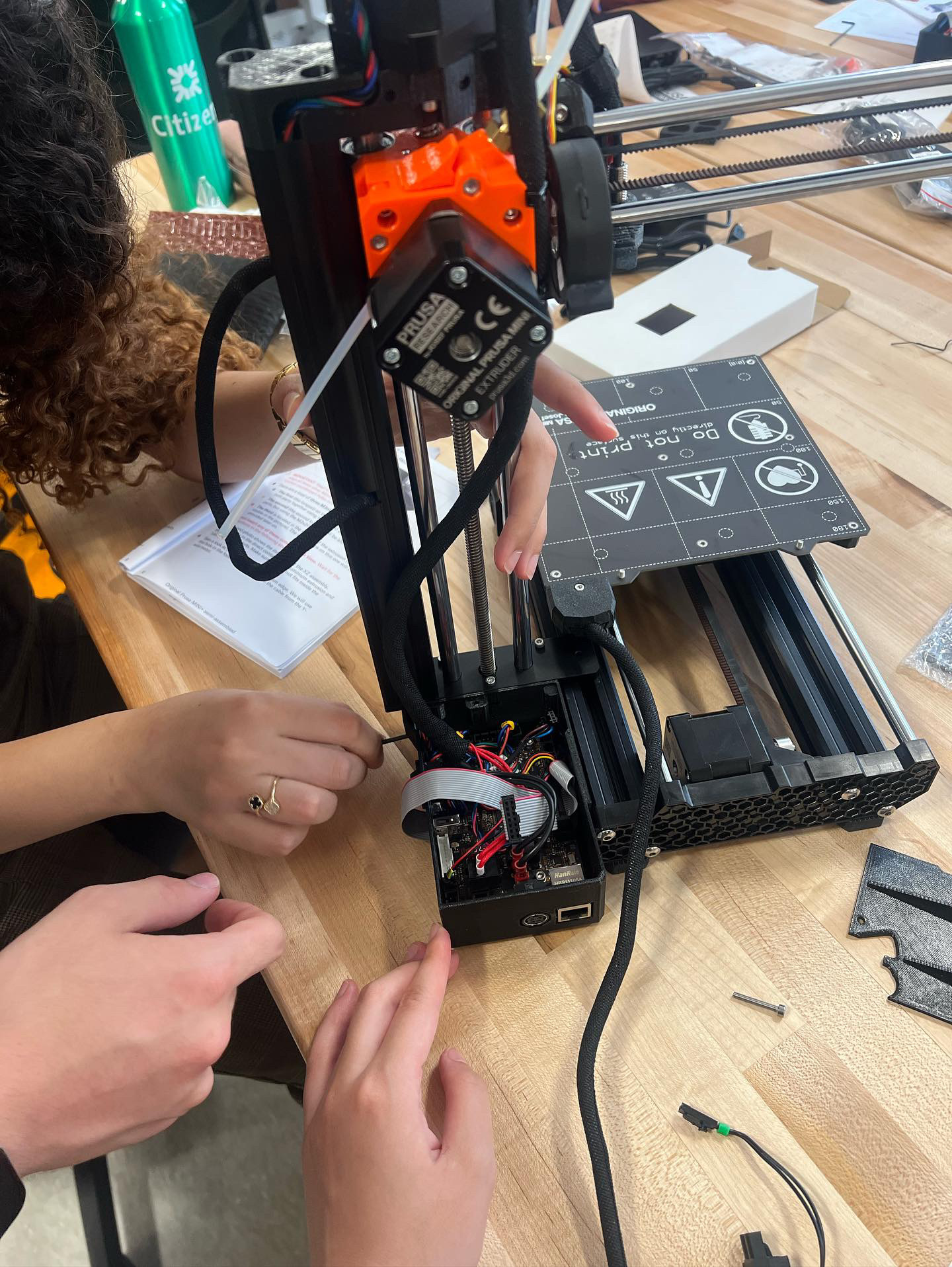

Our construction of the 3D printer was accompanied by a manual that, while comprehensive, occasionally left us grappling with confusion over screw placements. Clearer visual aids and labeled parts would have expedited the process, making it more user-friendly for beginners. Conversely, the step-by-step instructions helped us maintain a steady workflow, ensuring that we didn't miss any critical components.

Calibration

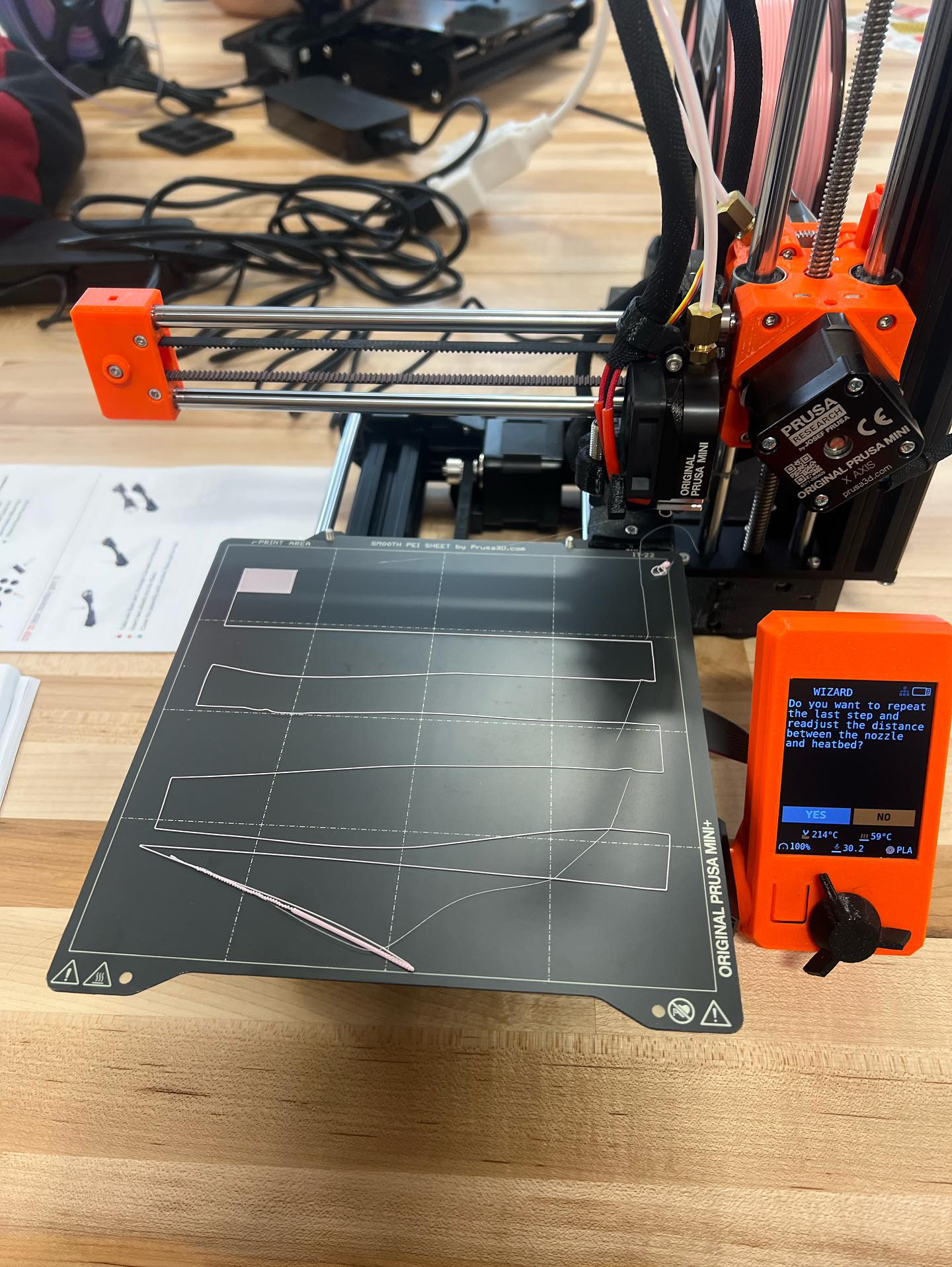

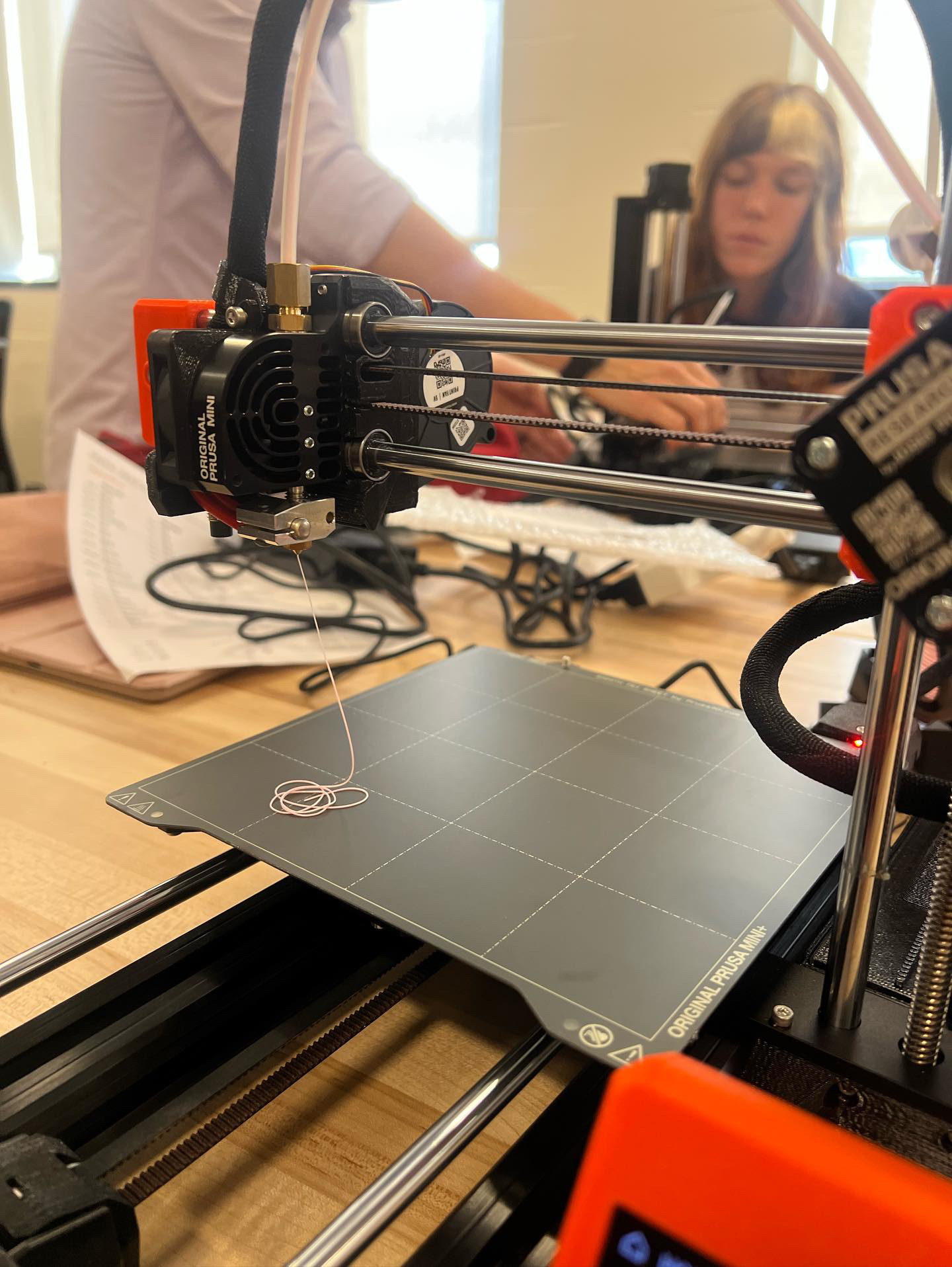

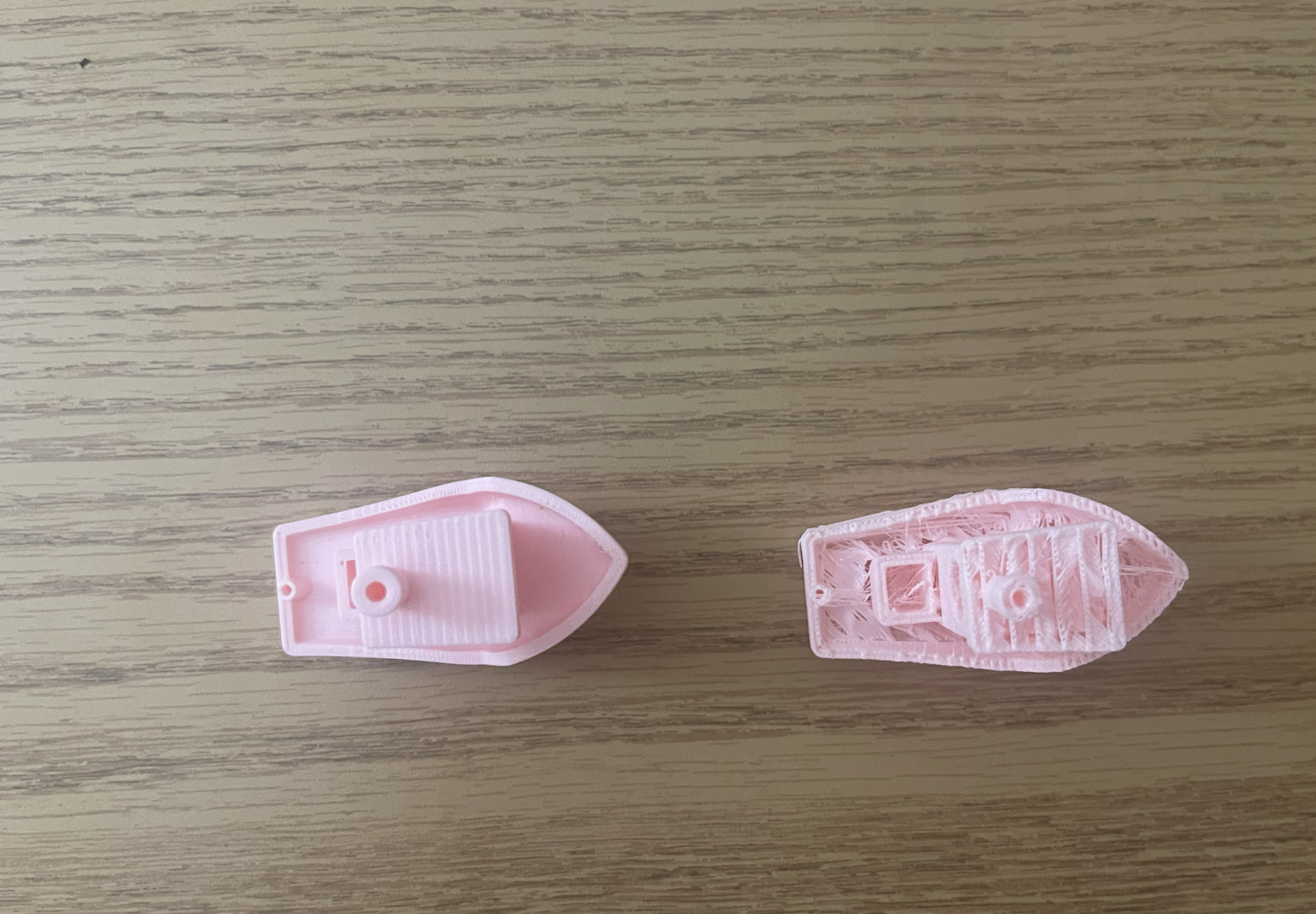

Calibrating our printer proved to be a learning experience, particularly when it came to selecting the appropriate filament settings. Initially, we struggled with the PLA filament, unaware of its higher temperature requirements. This led to prints that were less structurally sound, characterized by stringiness.

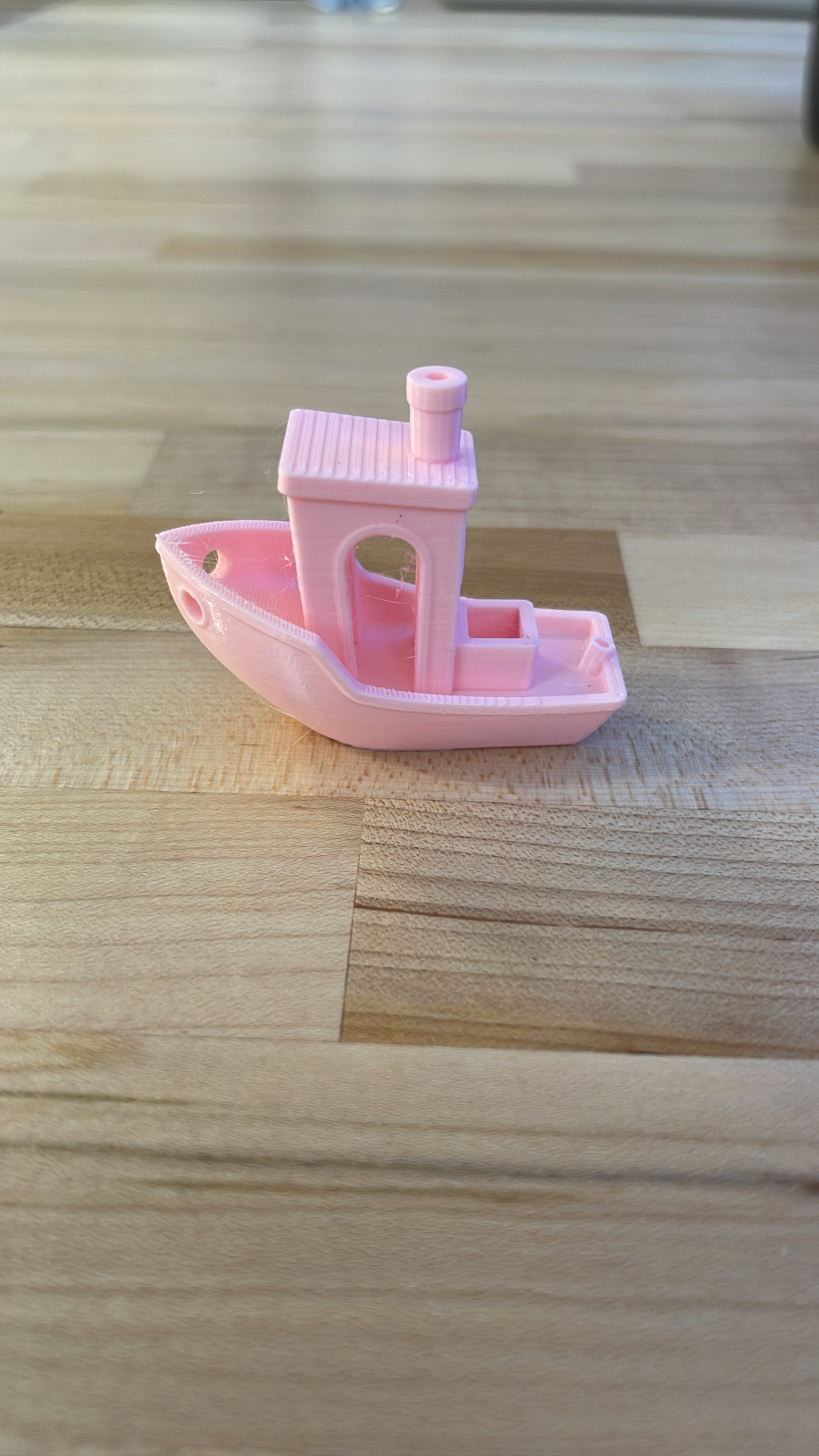

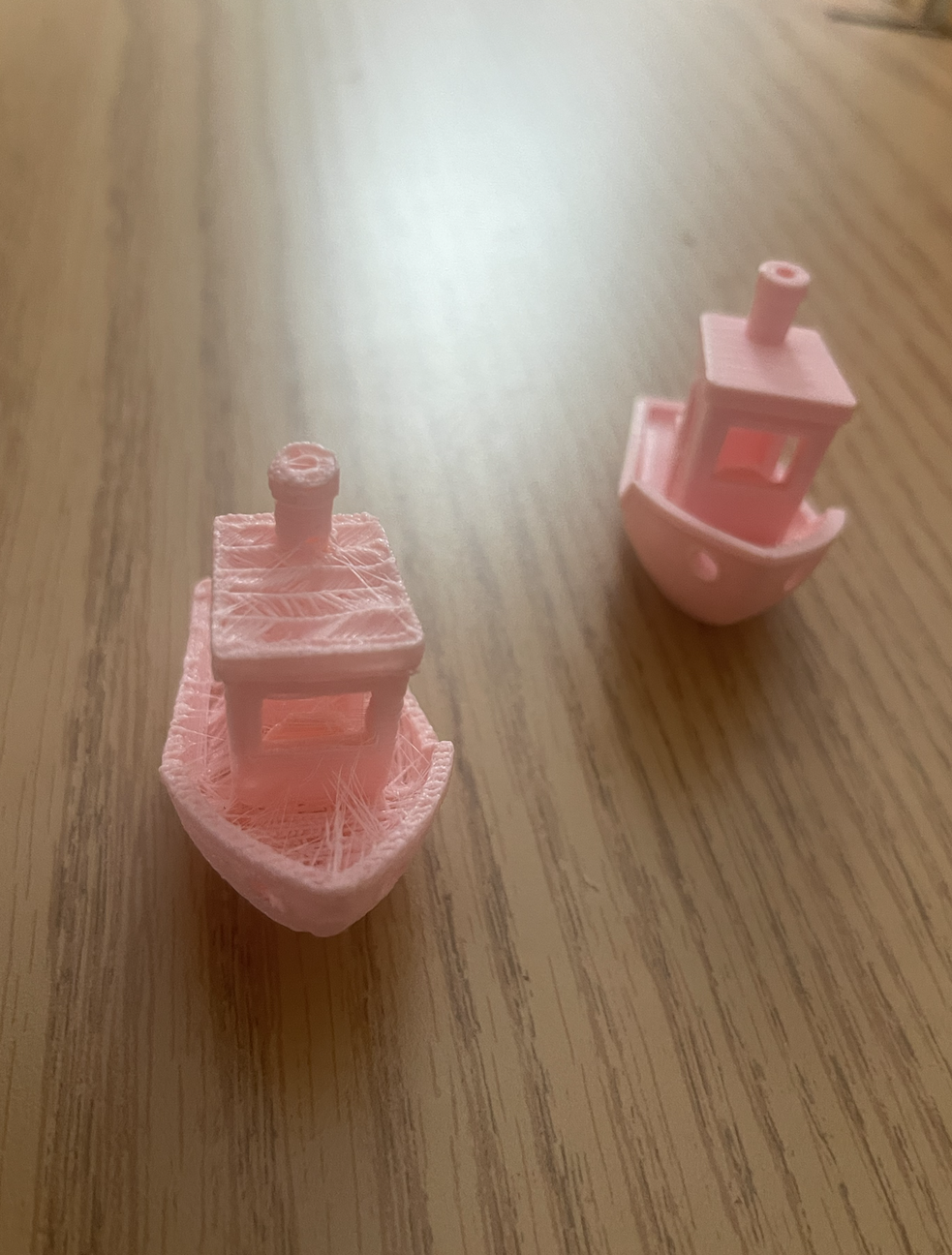

Comparing our Benchy to the idealized version, it became evident that adjusting the temperature settings could significantly enhance print quality. A higher temperature setting would minimize stringiness and result in a more robust final product. To achieve this, we should have undertaken thorough research on the filament's properties beforehand, preventing unnecessary setbacks.

Calibration Similarities

Despite the initial challenges, our Benchy exhibited notable structural stability, even with the filament's flexibility. The resemblance to the idealized Benchy was evident, showcasing the printer's capabilities. By addressing the temperature issue, we could have achieved an even closer match.

Calibration Differences and Fixes

The second Benchy, suffered from fragility due to insufficient reinforcement. We learned that modifying parameters like layer height, infill, and shell perimeters could significantly impact print time and quality.

In our case, altering these settings drastically reduced print time, but at the cost of print quality. Future endeavors will require a balanced approach to achieve efficiency without compromising the final output's integrity. Increased infill and structural support would likely have fortified the Benchy, rendering it less prone to breakage.

Project Narrative

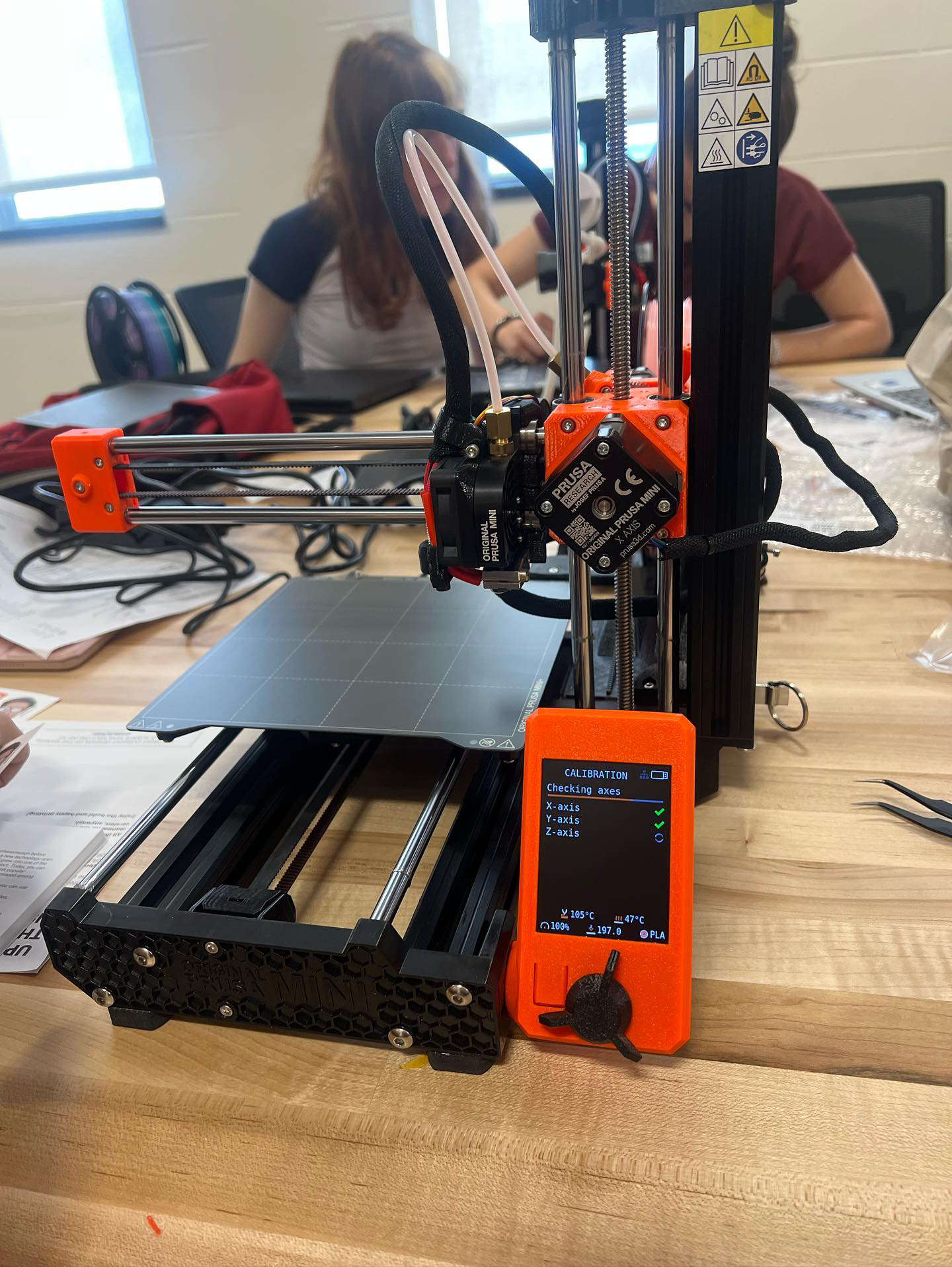

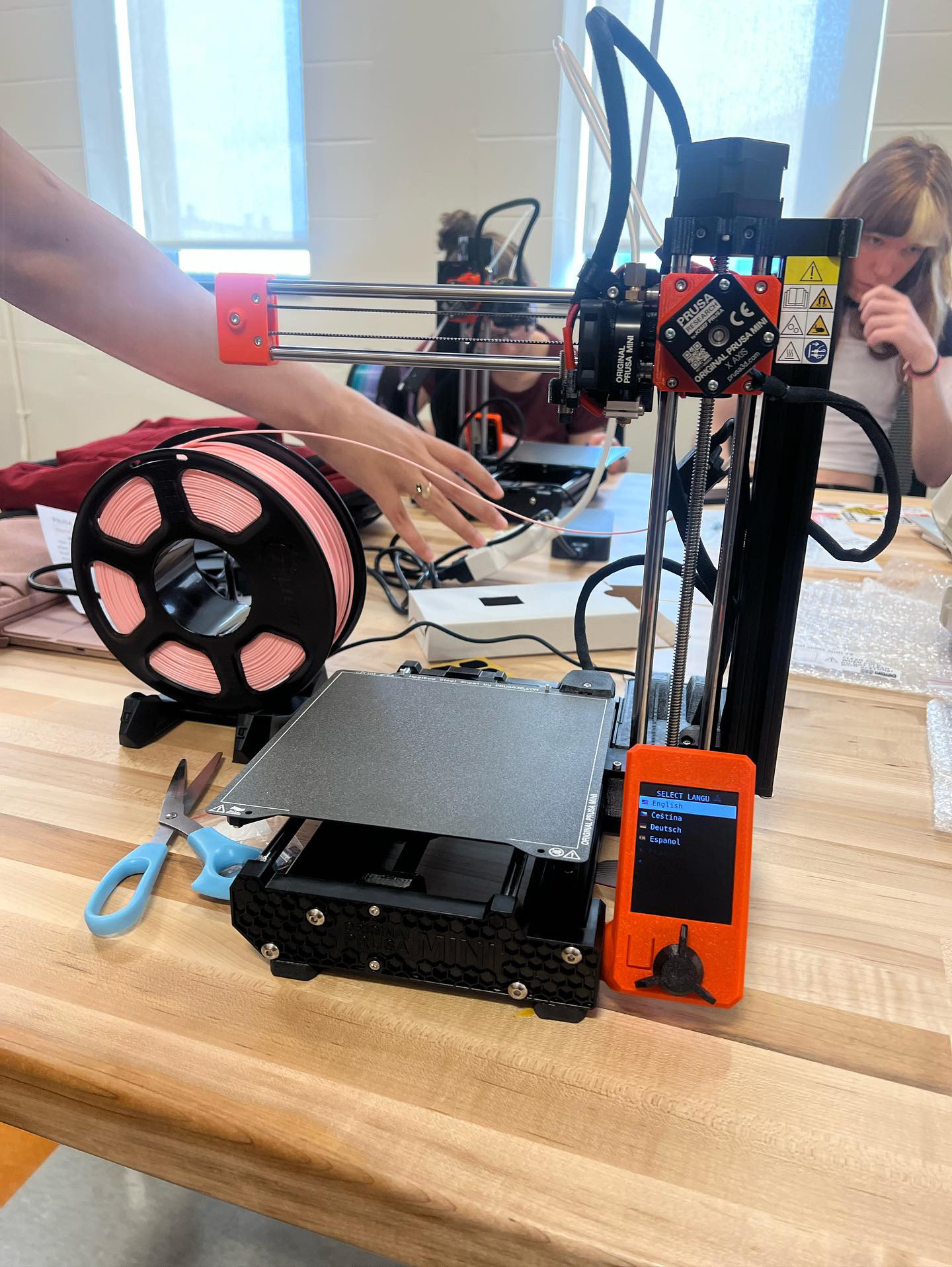

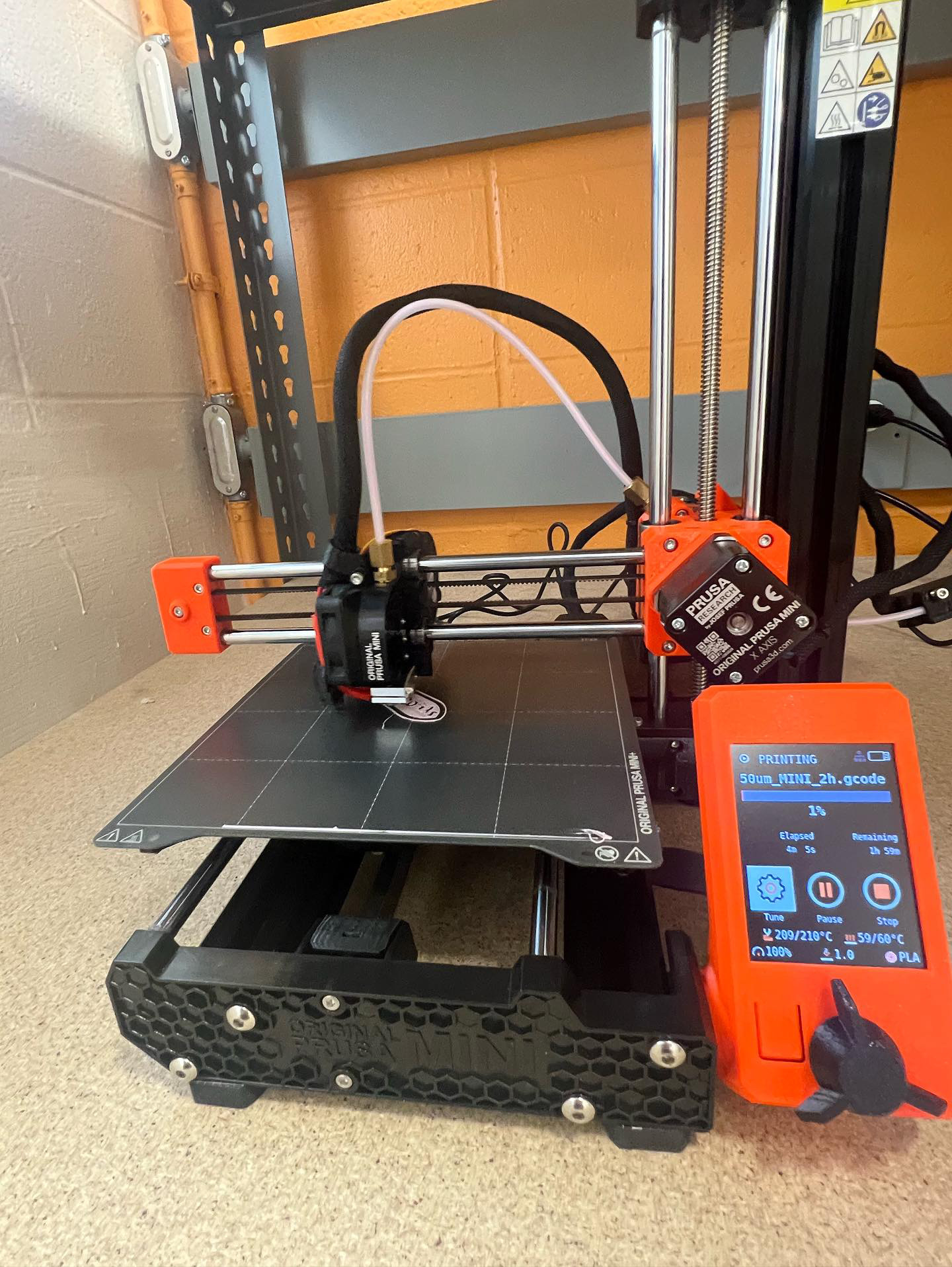

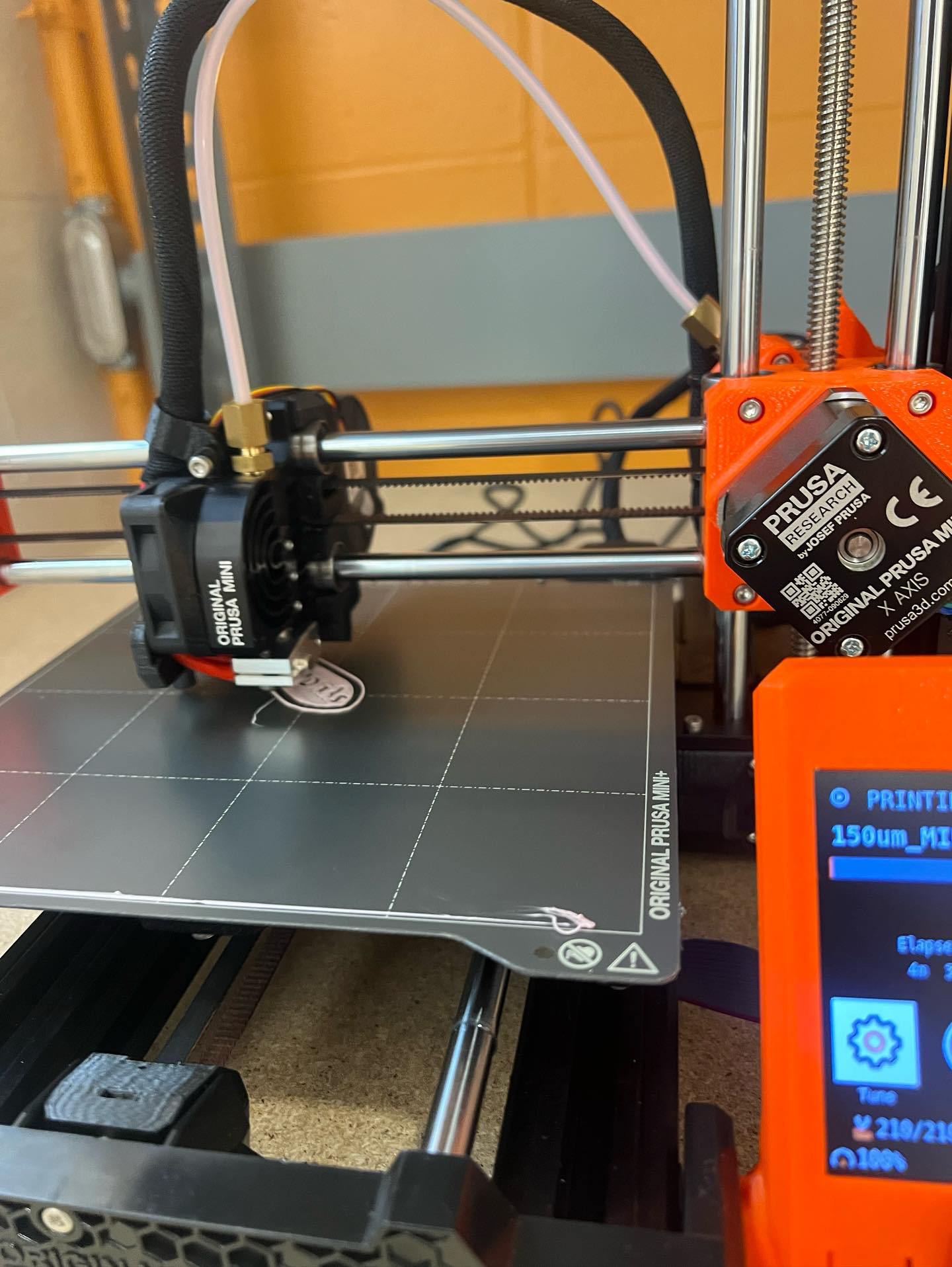

Our journey began with the assembly of the Prusa Mini+ 3D printer, a task that proved to be more about deciphering instructions than complex engineering. Through collaborative efforts and inquiries to our professors and TA, Isabel and I overcame the challenges posed by the instruction manual. We successfully assembled the printer in a relatively short timeframe.

Our first print, the standard 3D Benchy, was a testament to the printer's capabilities, with a near-perfect outcome achieved in about an hour and 15 minutes. However, our experimentation with settings during the second print revealed the delicate balance between speed and quality. Ultimately, we reached a print time of 39 minutes, but the trade-off was a noticeable decrease in quality, accompanied by stringiness and fragility.

Conclusion

Looking back, this project highlighted the importance of thorough documentation, extensive research, and careful calibration in the field of 3D printing. It was a journey marked by both challenges and enlightening moments, ultimately shaping our grasp of the intricate balance between efficiency and precision in the 3D printing realm. As we contemplate future projects, we carry with us the insights gleaned from assembling our Prusa Mini+ and perfecting the art of calibration for great outcomes.